Family-friendly Vinyl Flooring

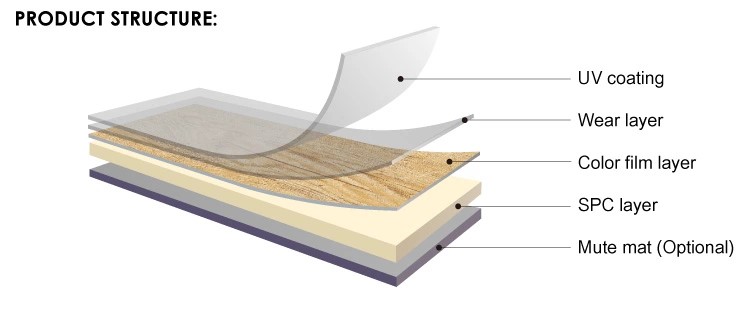

Family always comes first when we make decisions in our daily life or business activities. Our SPC Vinyl flooring is an outcome based on rigorous R&D of raw material, cutting-edge production technology, and strict quality control, through which we are able to provide the totally Family-friendly Vinyl Floorings to all households.

Nowadays, we spend a lot of time indoor, our family member’s healthiness and wellbeing are much dependent on the air quality in our living rooms. This plank is E1 and Floor Score certified, which is the European / US lowest formaldehyde emissions certificates. Its protective wear layer keeps your floor anti-slip. Plus its UV coating, the plank is anti-microbial, anti-bacterial and very easy to clean. A wet-mop can do the job good enough. When your little kids play around on the flooring, there is nothing to be worried about if he or she would be keeping hygiene. Even your four-leg family (dogs and cats) will be enjoying more playing on this Family-friendly Vinyl Flooring.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

5mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.7mm. (28 Mil.) |

|

Width |

7.25” (184mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Click |

|

|

Application |

Commercial & Residential |

|

SPC RIGID-CORE PLANK TECHNICAL DATA |

||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |