LVT Flooring Click SPC Rigid Core Flooring

Compared with traditional flooring such as Luxury Vinyl Tile, WPC, hardwood flooring, the biggest advantage of SPC Rigid Core Flooring is unparalleled durability, affordability and 100% waterproof.

The wide range of options is preferable for those who want to be able to customize the look of their home. It can be installed in areas of the home such as laundry rooms, bathrooms, basements, and kitchens. The waterproof feature also makes this board more stable in environments where moisture and temperature can fluctuate.

Licensed by the Unilin company, we use the German HOMAG slotting machine to ensure the processing accuracy of the interlocking click system. It is DIY-friendly, you can cut to size with a utility knife and install on your own.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

4.5mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

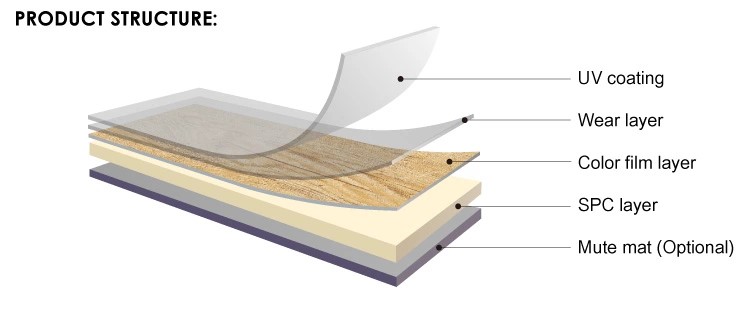

Wear Layer |

0.5mm. (20 Mil.) |

|

Width |

6” (152mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Click |

|

|

Application |

Commercial & Residential |

|

SPC RIGID-CORE PLANK TECHNICAL DATA |

||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |