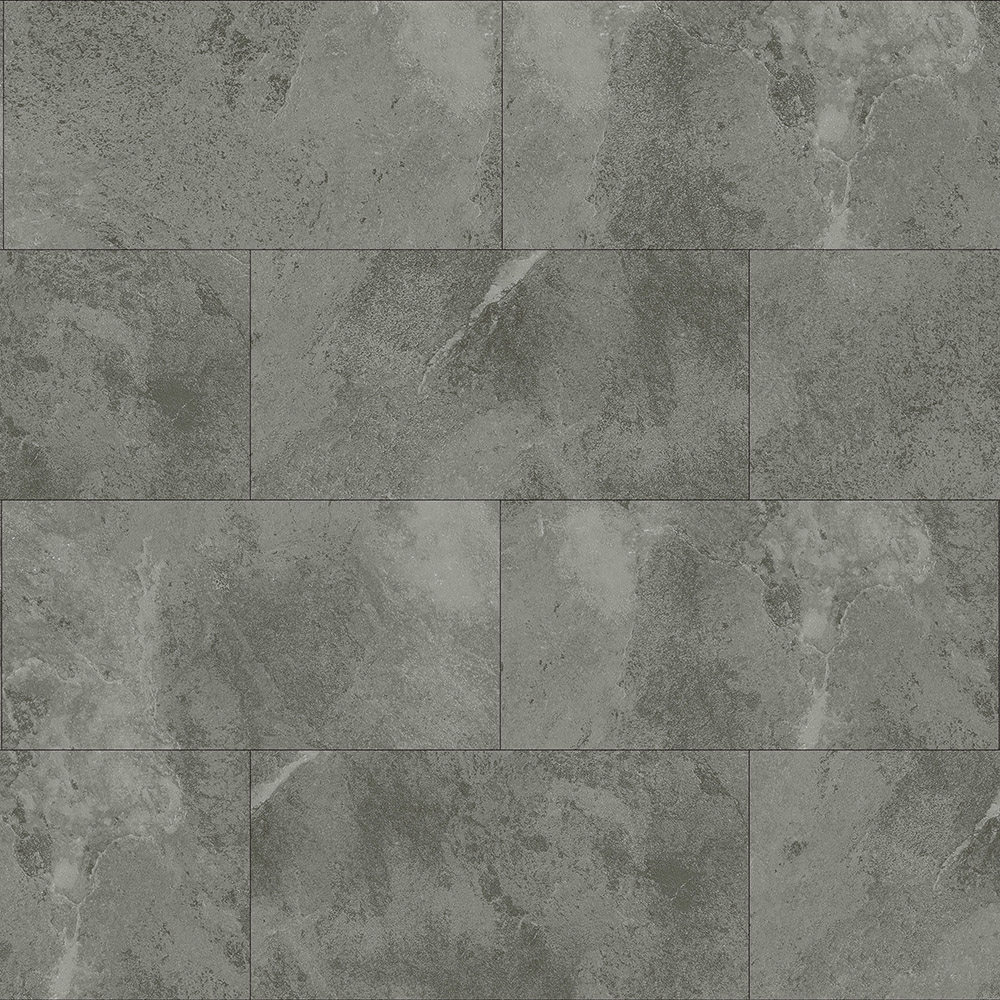

OEM manufacturer Spc Vinyl Plank Tiles - Contemporary industrial style Concrete SPC Vinyl Flooring – TopJoy

OEM manufacturer Spc Vinyl Plank Tiles - Contemporary industrial style Concrete SPC Vinyl Flooring – TopJoy Detail:

SPC flooring has attracted more consumers in the year 2022 thanks to its advantages in water resistance, safety, durability, and dimensional stability. Comprised of limestone powder and polyvinyl chloride, this type of vinyl plank has an ultra-rigid core, therefore, it won’t swell in wet rooms like kitchens, bathrooms, basements, etc., and also won’t expand or contract much in case of temperature change. The hard surface also has a wear layer and a UV coating layer. The thicker the wear layer, next to the rigid core, the more durable it will be. The UV coating layer is the layer that provides easy maintenance and scratch-resistance properties. With innovations in the flooring industry, now we have not only a classy wood look but also modern stone and concrete patterns, which are available in size of 12”x24”, 18”x24” and 18 1/4”x36 1/4” and we are developing square shape that looks like real tiles.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

4mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.2mm. (8 Mil.) |

|

Width |

7.25” (184mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Locking System |

|

|

Application |

Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

Packing Infornation:

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |

Product detail pictures:

Related Product Guide:

Cooperation

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for OEM manufacturer Spc Vinyl Plank Tiles - Contemporary industrial style Concrete SPC Vinyl Flooring – TopJoy , The product will supply to all over the world, such as: Russia , Amman, Thailand , Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.