Walnut SPC Vinyl Click Flooring Supplier

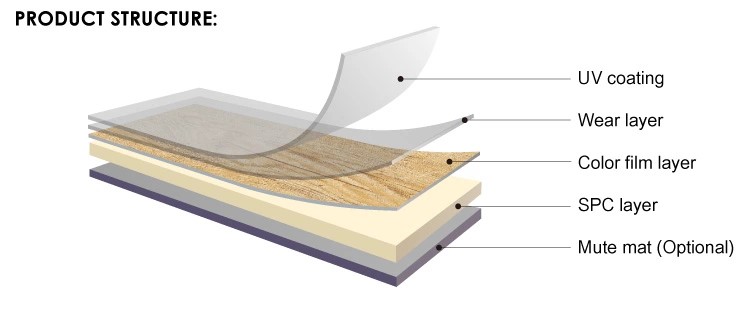

Our SPC walnut vinyl flooring is 100% waterproof product. What’s more, the dimension of our flooring is more stable when there is extreme temperature fluctuation. The surface of our flooring is harder than hardwood flooring, because the main material of SPC flooring is limestone powder and it has perfect wear layer and UV coating. So, people do not worry about the scratch during their daily life. Our flooring could be used in the high traffic commercial places as well, such as shopping malls, schools, restaurants and so on. As the fact of its low price and beautiful wood grains, this walnut SPC flooring is hot selling now. We also have 50 more different colors of walnut looks SPC Flooring in our stock. We can customize your own designing of the flooring looks with the economic price and perfect performance. Please consider the environmental protection and give up buying the hardwood flooring and, we should advocate of using the recyclable materials for everywhere we could.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

4mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.3mm. (12 Mil.) |

|

Width |

7.25” (184mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Click |

|

|

Application |

Commercial & Residential |

|

SPC RIGID-CORE PLANK TECHNICAL DATA |

||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |