Waterproof Oak Wooden Spc Vinyl Flooring

Every wise property owners should take advantage of SPC vinyl flooring to update their room or offices with the latest trending flooring. The SPC Vinyl flooring should be your first choice with for being durable, light weight, versatile and low maintenance requirements.

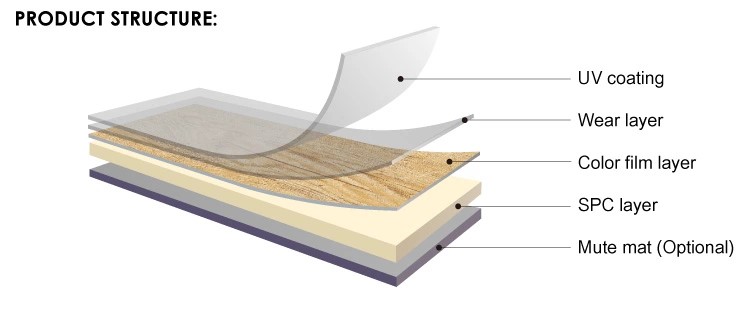

SPC Vinyl flooring, or Rigid core Vinyl flooring as it’s also known, offers comfort in hard-surface flooring that no other can compare, while at the same time it is one of the most affordable flooring options. Because SPC Vinyl floor is made of limestone composite PVC, it offers you with softer and warmer underfoot feeling than the other hard surface floors. SPC Vinyl flooring is also incredibly durable and easy to maintain.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

4mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.3mm. (12 Mil.) |

|

Width |

7.25” (184mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Click |

|

|

Application |

Commercial & Residential |

|

SPC RIGID-CORE PLANK TECHNICAL DATA |

||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |